The final appearance of a piece of candy is often what captivates the consumer, transforming a simple confection into a gleaming object of desire. Achieving that perfect, glossy finish or a smooth, matte coating is a critical step in confectionery production, one that relies heavily on specialized equipment and precise techniques. At the heart of this transformative process are two primary methods employed by candy polishing machinery: syrup panning and powder polishing. While both methods aim to enhance the candy’s aesthetics, texture, and stability, they achieve these results through fundamentally different principles and are suited to distinct product categories.

The Fundamental Role of Candy Polishing Machinery in Confectionery Production

Candy polishing machinery serves a purpose far beyond mere aesthetics. While creating an attractive, high-gloss shine or a uniform, matte finish is a primary function, the process is integral to the product’s quality, shelf life, and brand identity. The core principle behind all candy polishing machinery is the controlled application of a coating substance onto a center core through a tumbling action. This action ensures even distribution and gradual building of the coating layer. The benefits are multifold. Firstly, the coating acts as a protective barrier, sealing in moisture for soft centers or protecting against ambient humidity for hygroscopic ingredients. This protection is crucial for extending the product’s shelf life and maintaining its intended texture. Secondly, the polished surface improves the product’s handling characteristics, reducing stickiness and making it more pleasant for the end-consumer to handle. For wholesalers and buyers, consistent and high-quality polishing is a direct reflection of a manufacturer’s attention to detail and commitment to quality. It signals a premium product and can significantly enhance brand perception in a competitive marketplace. The choice between syrup panning and powder polishing is, therefore, not arbitrary but a strategic decision based on the desired final product characteristics.

An In-Depth Look at Syrup Panning

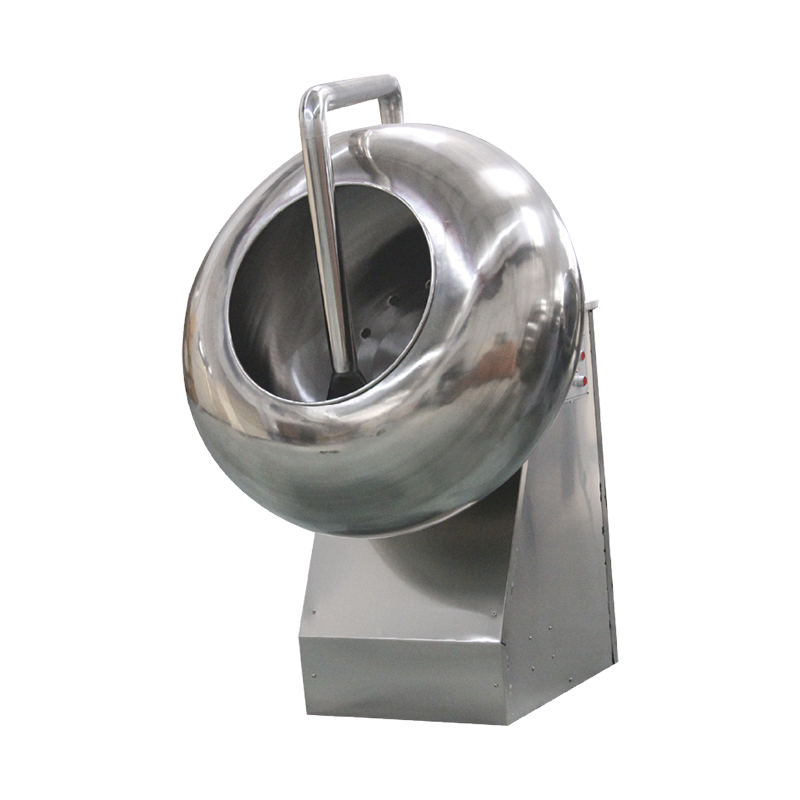

Syrup panning, often considered the more traditional and versatile of the two methods, is a process that involves the sequential application of liquid sugar-based syrups onto tumbling centers within a revolving drum or pan. The term “panning” itself is a historical reference to the copper pans originally used for this purpose, though modern candy polishing machinery now predominantly uses stainless steel for hygiene and control. This method is renowned for its ability to create a brilliantly glossy, hard, and durable shell around the candy center.

The Syrup Panning Process: A Cycle of Application and Drying

The syrup panning process is a cyclical operation that requires precision and control. It begins with the loading of the center cores—which can be anything from chocolate lentils and nuts to soft chews and jellies—into the revolving pan of the candy polishing machinery. The pan is set in motion, and the centers are gently tumbled to create a uniform bed. A measured amount of coating syrup, typically composed of sucrose, glucose, or other sugars dissolved in water and often containing additives like gum arabic for improved binding, is then applied or sprayed onto the tumbling centers. The key to successful syrup panning lies in the interplay between application and drying. After each syrup application, a drying phase is initiated. In modern candy polishing machinery, this is achieved by blowing controlled streams of cool, dry air over the tumbling goods. This air flow evaporates the water from the syrup, causing the sugar to crystallize and form a thin, solid layer. This cycle of syrup application followed by drying is repeated numerous times—sometimes dozens or even hundreds of times—to build up the coating to the desired thickness. The final stages often involve the application of a polishing syrup or a very thin glaze to smooth the surface, preparing it for the final polishing step that will impart the high-gloss shine.

Types of Syrup Panning: Hard Panning and Soft Panning

Syrup panning is broadly categorized into two types, distinguished primarily by the temperature of the syrup and the resulting characteristics of the coating.

Hard Panning employs syrups with a high sucrose concentration that are applied at or near room temperature. The drying air used is cool and has low humidity. This process results in a hard, brittle, and crunchy coating. The classic example of a hard-panned candy is a jawbreaker or a dragée, which features a thick, opaque, and vividly colored shell. The process is relatively slow, as the drying between layers must be thorough to prevent the layers from merging and becoming too thick at once, which could lead to cracking.

Soft Panning, in contrast, uses syrups with a higher content of non-crystallizing sugars like glucose or invert sugar. These syrups are often applied warm, and the drying process is less intense. The resulting coating is softer, more chewy, and less brittle than a hard pan. Popular examples of soft-panned candies include jelly beans (for their outer shell) and certain types of chocolate-covered raisins where the initial chocolate layer is often sealed with a soft-panned shell before polishing. The process is generally faster than hard panning due to the reduced drying requirements between layers.

Key Equipment and Operational Considerations for Syrup Panning

Modern candy polishing machinery for syrup panning has evolved significantly from simple revolving pans. While traditional inclined pans are still used for certain artisanal products, fully automated panning systems dominate industrial production. These systems are essentially enclosed, cylindrical or drum-shaped units that integrate spraying systems, air handling units for drying and exhaust, and sophisticated control panels. The automation allows for precise control over critical parameters such as pan rotation speed, syrup flow rate, spray pattern, air temperature, air volume, and air humidity. This level of control is essential for achieving batch-to-batch consistency, maximizing efficiency, and minimizing operator error. The design of this type of candy polishing machinery also prioritizes hygiene, with easy-clean surfaces and minimal crevices, and scalability, allowing manufacturers to select a machine size that matches their production volume.

An In-Depth Look at Powder Polishing

Powder polishing, also known as wax polishing or cleaning, is a secondary finishing process applied to candies that already have a complete outer shell, typically achieved through syrup panning. Unlike the building process of syrup panning, powder polishing is a surface-level treatment designed to smooth imperfections and impart a high-gloss, professional finish. It is a simpler, faster, and more straightforward process that serves as the final step for many polished confections.

The Powder Polishing Process: Smoothing and Sealing

The powder polishing process takes place after the candy centers have been coated with their final shell and are fully dried and hardened. The candies are loaded into a polishing pan, which can be the same drum used for syrup panning or a dedicated polishing unit. While the pan is rotating, a small quantity of a fine, food-grade powder is added. The most common polishing agents are beeswax, carnauba wax (a vegetable wax), candelilla wax, or mixtures thereof. These waxes are often combined with inert substances like talc or starch to improve their application properties. As the pan rotates, the tumbling action causes the wax powder to be rubbed against the surface of the candies. The friction generated by the continuous tumbling melts the wax slightly, allowing it to spread evenly across the candy’s surface. This action fills in microscopic pores and imperfections on the shell, creating an exceptionally smooth surface. Once a uniform coating is achieved, the continued tumbling action buffs the wax layer to a brilliant, high-gloss shine. In some applications, a small amount of a polishing solution, such as a wax dispersed in an alcohol base, may be used in conjunction with or instead of dry powder to achieve a specific level of shine.

Applications and Functional Benefits of Powder Polishing

The primary application of powder polishing is on hard-panned candies like dragées, sugar-coated chocolates, and certain tablet forms. Its benefits are both aesthetic and functional. The most obvious benefit is the deep, glossy luster it provides, which significantly enhances the product’s visual appeal and perceived quality on the shelf. However, the functional benefits are equally important. The wax layer acts as a final sealant, providing an extra barrier against moisture ingress or loss, which further protects the product’s texture and extends its shelf life. It also helps to prevent the candies from sticking together in the package. Furthermore, the smooth, waxed surface makes the candy more pleasant to handle and eat. For buyers and wholesalers, a consistently well-polished product indicates a manufacturer that has mastered the entire production chain, from core enrobing to final finishing, ensuring a superior product that will perform well in retail environments.

Equipment for Powder Polishing

The candy polishing machinery used for powder polishing can be identical to that used for syrup panning, particularly the versatile revolving drum systems. However, the requirements are often less demanding. Since no drying air is required, the process can be performed in simpler, non-ventilated pans. For high-volume production, dedicated polishing units are available. These are often designed with interior baffles or a special internal surface texture to maximize the tumbling and friction action, which is crucial for an efficient and high-quality polish. The key operational parameters for powder polishing are rotation speed, polishing time, and the precise quantity of polishing agent used. Too much wax can lead to a cloudy or greasy appearance, while too little will result in an incomplete shine. Modern automated candy polishing machinery can be programmed to add precise amounts of powder at set intervals and to run for a predetermined time, ensuring a consistent result with every batch.

Comparative Analysis: Choosing Between Syrup Panning and Powder Polishing

The decision to use syrup panning, powder polishing, or a combination of both is a fundamental one in confectionery production. The following table provides a clear, side-by-side comparison of the two methods to aid in this decision-making process.

| Feature |

Syrup Panning |

Powder Polishing |

| Primary Function |

To build a coating shell layer by layer. |

To smooth and shine an existing shell. |

| Coating Material |

Liquid sugar syrups (sucrose, glucose). |

Fine powders (beeswax, carnauba wax, talc). |

| Nature of Process |

Cyclical (application-drying). |

Linear (application-buffing). |

| Process Time |

Long (hours to days, depending on thickness). |

Short (minutes to a few hours). |

| Final Coating |

Can be hard and crunchy or soft and chewy. |

Thin, glossy, protective wax film. |

| Product Examples |

Jawbreakers (hard pan), Jelly beans (soft pan). |

Polished chocolate dragées, Smarties. |

| Required Machinery |

Sophisticated candy polishing machinery with syrup spray and air drying capabilities. |

Can use the same panning equipment, but without the need for drying air; simpler dedicated polishers are also common. |

This comparison highlights the complementary nature of the two processes. It is crucial to understand that powder polishing is almost always a subsequent step to syrup panning. A candy manufacturer would first use syrup panning to build the desired shell—for instance, a colored sugar shell on a chocolate lentil—and then use powder polishing in a separate, final operation to give that shell a high-gloss finish. The two methods are not mutually exclusive but are sequential stages in the production of many high-quality polished confections.

Key Decision Factors for Manufacturers

When selecting the appropriate method and investing in the right candy polishing machinery, manufacturers must consider several factors. The first and most important is the desired product specification. What is the target texture: a hard shell or a soft one? What is the required visual finish: a bright gloss or a more satin sheen? The answer to these questions will direct the process. The production scale and throughput requirements are also critical. Syrup panning is a time-intensive process, and a manufacturer with high-volume targets will need to invest in automated, high-capacity candy polishing machinery to make it economically viable. Powder polishing, being a faster process, has less impact on overall line throughput. Finally, operational expertise and cost play a role. Syrup panning requires a higher level of technical skill to manage syrup formulations, drying parameters, and process timing. Powder polishing is relatively simpler to control and execute consistently.

Conclusion: The Synergy of Two Essential Methods

In the world of confectionery manufacturing, the transformation of a simple center into a beautifully finished candy is a testament to the precision and capability of modern candy polishing machinery. The two main methods, syrup panning and powder polishing, serve distinct yet interconnected purposes. Syrup panning is the foundational, constructive process, responsible for creating the product’s identity through the building of a hard or soft shell. It is a complex dance of chemistry and mechanical engineering, requiring sophisticated equipment and skilled operation. Powder polishing, by contrast, is the final, aesthetic touch. It is the masterstroke that smooths, seals, and shines, elevating a well-coated candy to a premium, market-ready product. For anyone involved in the confectionery industry, from equipment designers and production managers to wholesalers and buyers, a clear understanding of these two methods is indispensable. It allows for informed conversations about product capabilities, equipment needs, and quality benchmarks. Ultimately, the synergy between syrup panning and powder polishing within advanced candy polishing machinery is what delivers the consistent, high-quality, and visually stunning confections that consumers know and love.

中文简体

中文简体 English

English Français

Français عربى

عربى