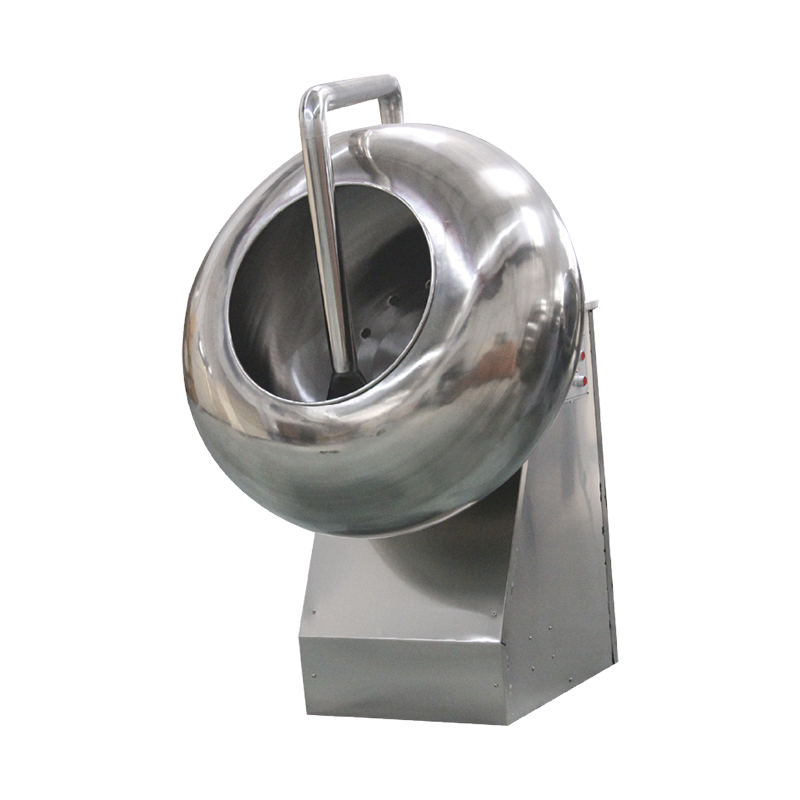

Polishing Capabilities: The machinery is specifically designed to polish the surfaces of chocolates and candies, removing any imperfections and enhancing their appearance. It helps achieve a smooth, glossy finish, making the products visually appealing and attractive to consumers.

Efficient Operation: Chocolate and candy polishing machinery is engineered for efficient operation, allowing for high throughput and productivity. It can handle large volumes of confectionery products, ensuring a consistent and timely polishing process.

Customizable Settings: The equipment often comes with adjustable settings, such as speed, pressure, and polishing time, to accommodate different types of chocolates and candies. This flexibility enables manufacturers to achieve the desired level of polishing for their specific products.

Versatility: Chocolate and candy polishing machinery is versatile and can be used for various types and sizes of confectionery products. It can handle different shapes, textures, and coatings, making it suitable for a wide range of candies and chocolates in different production scenarios.

Quality Assurance: By using polishing machinery, confectionery manufacturers can ensure consistent quality in their products. The equipment helps remove surface irregularities, such as scratches or air bubbles, resulting in a more uniform appearance and texture.

Time and Labor Savings: Automated chocolate and candy polishing machinery significantly reduces the time and labor required for manual polishing. It streamlines the process, allowing manufacturers to focus on other production tasks, thereby increasing overall operational efficiency.

Hygiene and Food Safety: Many polishing machinery units are designed with food-grade materials that meet strict hygiene and safety standards. They are easy to clean and maintain, minimizing the risk of contamination and ensuring compliance with food industry regulations.

Extended Shelf Life: Polishing machinery can contribute to extending the shelf life of chocolate and candy products. By creating a smooth surface, it helps reduce the exposure of the products to air and moisture, thereby preserving their freshness and flavor for a longer period.

Enhanced Customer Satisfaction: The polished appearance of chocolates and candies adds to their visual appeal, attracting customers and enhancing their overall experience. Aesthetically pleasing products are more likely to leave a positive impression on consumers, leading to increased customer satisfaction and repeat purchases.

Competitive Advantage: Investing in chocolate and candy polishing machinery can give confectionery manufacturers a competitive edge in the market. It allows them to produce high-quality, visually appealing products more efficiently, positioning them favorably among consumers and competitors.

中文简体

中文简体 English

English Français

Français عربى

عربى