The chocolate and candy polishing process is a critical step in confectionery production, ensuring a glossy, uniform finish that enhances product appeal. Chocolate & candy polishing machinery equipment comes in two primary operational modes: batch processing and continuous processing. Each method has distinct advantages, limitations, and suitability depending on production scale, product variety, and efficiency requirements.

1. Understanding batch chocolate & candy polishing machinery equipment

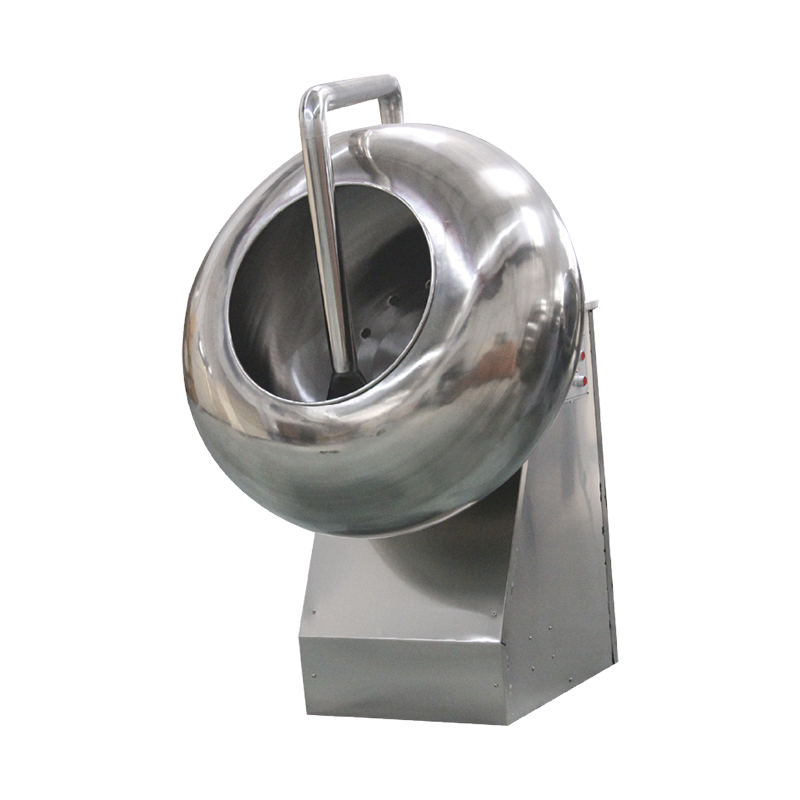

Batch chocolate and candy polishing machines process products in discrete quantities, where each cycle must be completed before the next begins. These systems are common in small to medium-scale production or when handling multiple product variations.

Key characteristics of batch polishing machines

- Manual or semi-automated loading/unloading – Operators introduce raw chocolates or candies into the polishing drum or tumbling machine before each cycle.

- Flexibility in product changes – Ideal for manufacturers producing limited editions or varying recipes, as adjustments can be made between batches.

- Lower initial investment – Typically more affordable than continuous candy shine machines, making them suitable for startups or artisanal producers.

- Longer processing time per unit – Since each batch operates independently, overall throughput may be slower compared to continuous systems.

Common types of batch chocolate and candy surface finishing machines include rotary drum polishers and vibratory tumblers, which rely on controlled tumbling to achieve an even glaze.

2. Exploring continuous chocolate & candy polishing machinery equipment

Continuous chocolate and candy polishing line systems are designed for high-volume production, where products move seamlessly through different polishing stages without interruption.

Key characteristics of continuous polishing equipment

- Fully automated operation – Conveyor belts or spiral systems transport products through polishing, glazing, and drying zones with minimal manual intervention.

- Higher output efficiency – Suitable for large-scale chocolate manufacturing equipment where thousands of units must be processed daily.

- Consistent quality control – Automated sensors and feedback loops ensure uniform coating thickness and shine across all products.

- Higher capital and maintenance costs – Requires significant upfront investment and technical expertise for optimal operation.

Examples include inline candy coating machines and continuous chocolate enrobing and polishing equipment, often integrated into full confectionery production machinery lines.

3. Comparative analysis: Batch vs. continuous chocolate & candy polishing machinery

| Factor |

Batch Polishing Equipment |

Continuous Polishing Equipment |

| Production Scale |

Small to medium batches |

Large-scale, high-speed output |

| Flexibility |

High (easy product changeovers) |

Low (optimized for single product types) |

| Automation Level |

Manual or semi-automated |

Fully automated |

| Cost Efficiency |

Lower initial cost, higher labor cost |

Higher initial cost, lower per-unit cost |

| Processing Time |

Slower (per batch) |

Faster (continuous flow) |

| Maintenance Needs |

Simpler, less frequent |

Complex, requires regular servicing |

4. Choosing the right system for your production needs

Selecting between batch and continuous chocolate & candy polishing machinery equipment depends on several factors:

- Production volume – Small confectioners may prefer batch candy rotary polishing machines, while industrial manufacturers benefit from continuous chocolate finishing machines.

- Product diversity – If producing multiple candy types with different glaze requirements, batch systems offer greater adaptability.

- Budget constraints – Continuous confectionery polishing machinery demands higher capital but reduces long-term labor costs.

- Space and infrastructure – Continuous lines require more floor space and integration with other chocolate production automation equipment.

5. Technological advancements in chocolate & candy polishing machinery

Modern innovations, such as AI-driven quality inspection and energy-efficient drying systems, are enhancing both batch and continuous polishing machines for chocolates and sweets. For example:

- Smart sensors now detect uneven glaze distribution in real-time.

- Eco-friendly polishing agents reduce waste in candy and chocolate tumbling machines.

The choice between batch and continuous chocolate & candy polishing machinery equipment hinges on production demands, scalability, and operational preferences. While batch systems excel in flexibility, continuous candy glaze polishing machinery dominates high-efficiency environments. Manufacturers must evaluate their specific needs before investing in confectionery line automation or traditional polishing solutions.

中文简体

中文简体 English

English Français

Français عربى

عربى