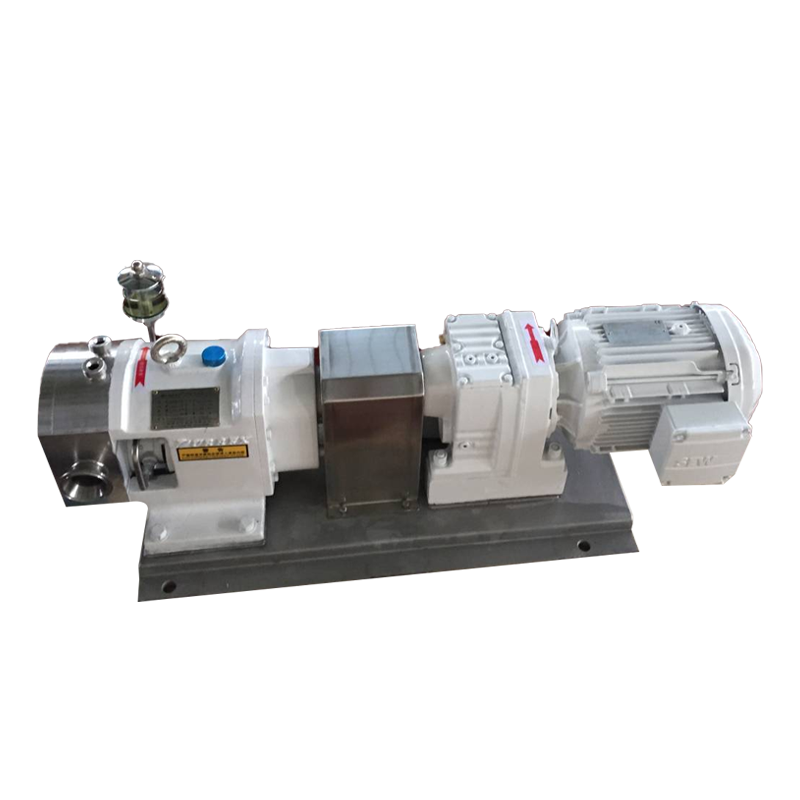

In the world of confectionery, efficient and precise chocolate delivery is crucial for ensuring consistent quality and meeting consumer demands. To address this need, a groundbreaking innovation has emerged: the

DTJ Delivery Pump Machinery Equipment. This cutting-edge technology promises to revolutionize the chocolate delivery process, offering enhanced efficiency, accuracy, and versatility. In this article, we delve into the remarkable capabilities of the DTJ Delivery Pump and explore how it is reshaping the chocolate industry.

Enhanced Efficiency for Chocolate Delivery

The DTJ Delivery Pump Machinery Equipment is designed to optimize the chocolate delivery process, streamlining production lines and minimizing wastage. With its advanced pumping mechanism, the equipment ensures a consistent flow of chocolate without any interruptions or clogs. This smooth and uninterrupted delivery eliminates production bottlenecks and maximizes overall efficiency, enabling manufacturers to meet increased demand while reducing production costs.

Precise and Accurate Delivery

One of the key challenges in chocolate manufacturing is maintaining consistent viscosity and temperature throughout the production cycle. The DTJ Delivery Pump tackles this issue by providing precise control over the flow rate, ensuring that the chocolate is delivered at the exact viscosity required for each production stage. Additionally, the equipment's temperature control system maintains the ideal temperature, preventing undesirable changes that could affect the chocolate's texture and quality. As a result, manufacturers can produce chocolates with consistent taste, texture, and appearance, delighting consumers with every bite.

Versatility and Adaptability

The DTJ Delivery Pump Machinery Equipment caters to the diverse needs of the chocolate industry, accommodating various types of chocolates, including milk, dark, and white chocolates, as well as specialized formulations. The equipment can handle different viscosities, from thin coatings to thick ganache, and is compatible with different production scales, from small artisanal chocolatiers to large-scale manufacturing facilities. Its flexibility and adaptability make it an indispensable tool for chocolate manufacturers seeking to expand their product offerings and meet the demands of a dynamic market.

Quality Control and Hygiene Standards

Maintaining high standards of quality and hygiene is paramount in the food industry, especially in chocolate production. The DTJ Delivery Pump Machinery Equipment incorporates innovative features that ensure stringent quality control and meet the strictest hygiene standards. The equipment is designed with easy-to-clean components and utilizes sanitary materials, preventing cross-contamination and facilitating thorough cleaning between production runs. By upholding impeccable hygiene practices, chocolate manufacturers can uphold their brand reputation and instill confidence in their consumers.

The Future of Chocolate Delivery

The DTJ Delivery Pump Machinery Equipment represents a significant leap forward in chocolate delivery technology. Its ability to enhance efficiency, ensure precise delivery, and meet versatile production needs positions it as a game-changer in the chocolate industry. As manufacturers strive to keep up with the evolving tastes and demands of consumers, the DTJ Delivery Pump offers a reliable and innovative solution that can elevate their production processes and deliver exceptional chocolates consistently.

With the DTJ Delivery Pump Machinery Equipment, chocolate manufacturers have access to a state-of-the-art solution for optimizing their production lines and delivering high-quality chocolates. Its ability to enhance efficiency, ensure precision, accommodate diverse chocolate types, and uphold hygiene standards makes it an indispensable tool in the modern chocolate industry. As this innovative technology continues to gain traction, we can expect a transformation in the way chocolates are produced, setting new benchmarks for quality, consistency, and customer satisfaction.

中文简体

中文简体 English

English Français

Français عربى

عربى