In the world of global confectionery, few brands command the instant recognition and consumer loyalty enjoyed by this particular nougat, caramel, and peanut bar. For wholesalers and buyers, this popularity translates directly into predictable, high-volume sales. However, this commercial reliability is fundamentally dependent on a factor that often goes unnoticed by the end consumer: absolute consistency. Every single bar must look, feel, and weigh the same as the last. This unwavering uniformity is not a matter of chance; it is the direct result of a meticulously engineered and controlled snickers production line.

The question of consistency is paramount for buyers. Inconsistent product weight can lead to significant financial losses across the supply chain, from the manufacturer to the retailer. It can also violate regulatory standards for weight declaration. Therefore, understanding the sophistication behind the snickers production line is not merely a technical curiosity but a crucial element of supply chain confidence. The entire system—from the initial mixing of ingredients to the final packaging—is designed as an interlocking set of checks and balances where precision engineering and process control are paramount. We will explore this journey, highlighting the key stages where consistency is actively enforced and measured.

The Foundation of Consistency: Ingredient Preparation and Handling

Before any bar is formed, the foundational step of ensuring consistency begins with the raw materials. The snickers production line does not start with assembly but with rigorous ingredient standardization. The composition and physical state of the inputs—nougat, caramel, peanuts, and chocolate—are critical variables that must be controlled to achieve a uniform output.

The nougat, a key component for the bar’s structure, is prepared in large batches. The recipe is precise, but so is the aeration and mixing process. The density of the nougat is a carefully monitored parameter. If the density varies, the volume of nougat used for a given weight would change, immediately affecting the final bar size and mass. Similarly, the caramel is cooked to an exact temperature and viscosity. This ensures it flows consistently during deposition, creating a uniform layer that does not seep unevenly into the nougat base. The peanuts are sorted and graded by size and weight to ensure a consistent distribution. Using an uncontrolled mix of small and large pieces would lead to uneven filling, creating voids or dense clusters, which directly impacts the weight and structural integrity of the bar. This meticulous preparation of all components sets the stage for a stable and predictable manufacturing process, forming the first critical link in the chain of consistency.

Precision Forming: The Heart of the Operation

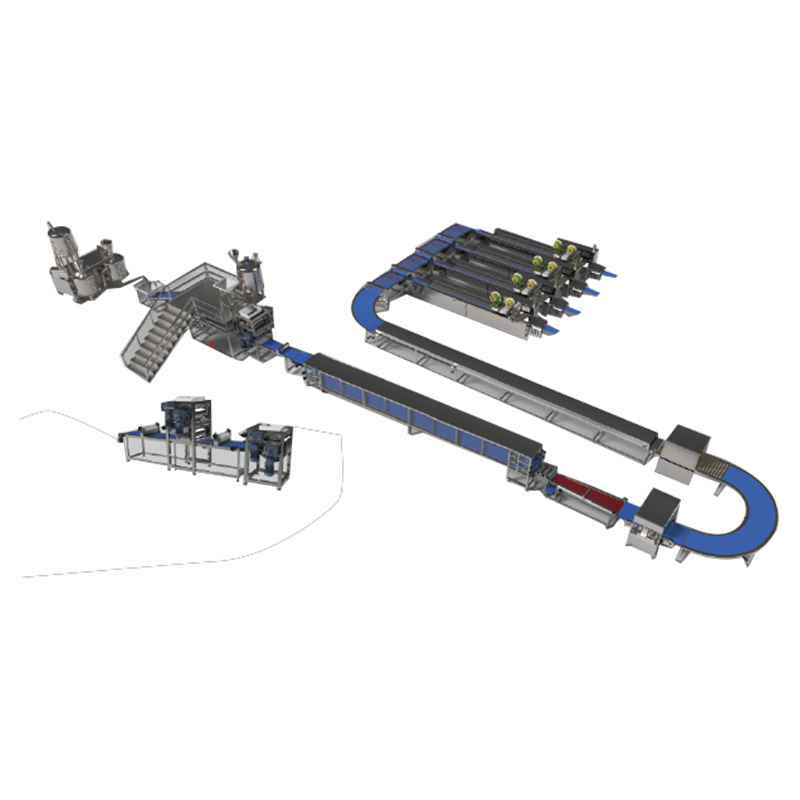

Once the ingredients are prepared to exacting standards, the snickers production line moves to its most critical phase: forming the core of the bar. This is where precision engineering takes center stage to define the bar’s fundamental dimensions and mass.

Layer Deposition and Extrusion

The process typically begins with the nougat. The prepared nougat mass is fed into an extrusion head or a roller system that shapes it into a continuous, perfectly dimensioned slab. The thickness, width, and density of this slab are continuously monitored. Even minor deviations in the slab’s profile would be compounded in later stages, making this initial forming operation vital. Following the nougat, a layer of caramel is precisely deposited. The caramel application is not a simple pouring operation; it is a metered process. Precision depositers are used, which function like sophisticated syringes, releasing an exact volume of caramel onto the moving nougat base. This volumetric control is a direct method of mass control, ensuring that every bar segment receives an identical amount of caramel. Finally, a pre-measured quantity of peanuts is distributed evenly across the caramel layer. The use of vibratory feeders or similar equipment ensures a single, consistent layer of nuts without clumping or gaps. This layered structure then moves into a cooling tunnel to set its form, solidifying the precise dimensions achieved in this stage.

Multi-Wire Cutting Systems

After the layered mass is cooled and set, it is cut into individual bars. This is a decisive moment for consistency, and the technology used is far from a simple guillotine. The snickers production line employs a multi-wire cutting system. In this process, an array of tightly spaced, high-tension wires passes through the continuous slab of product, cleaving it into distinct bars. The advantages of this system are numerous. Firstly, it creates a clean cut with minimal product deformation or waste (a critical factor for yield optimization), unlike a blade which can compress the product. Secondly, and most importantly for consistency, the wires are fixed at a precise distance from one another. This guarantees that every bar cut from the slab has an identical length and width. The combination of a controlled slab profile and a fixed-distance cutting system ensures that the core mass of every bar, before enrobing, is virtually identical. This level of control is a cornerstone for achieving the final weight target.

The Enrobing and Cooling Process: A Controlled Embrace

The next critical phase is the application of the chocolate coating. The enrobing process is a delicate balance; it must completely cover the bar without applying an excessive or inconsistent amount of coating, which would directly affect the final weight and appearance.

The enrobing section consists of a curtain of melted chocolate through which the bars pass on a conveyor. The key to consistency here is the control of several variables: the viscosity and temperature of the chocolate, the speed of the conveyor, and the design of the curtain itself. The chocolate must be held at a specific temperature to maintain its fluidity. If it is too viscous, it will coat too thickly and unevenly; if too thin, it will not provide adequate coverage. The chocolate tempering units on the snickers production line are responsible for maintaining this exact state. As the bars pass under the curtain, they receive a primary coat. They then move over a shaking mesh conveyor, which serves two purposes: it ensures the chocolate flows evenly to cover the entire bar, and it shakes off any excess coating. This removal of excess is a critical weight-control step. The amount shaken off is relatively consistent, leaving a uniform layer on every bar. Following enrobing, the bars enter a multi-zone cooling tunnel. The cooling rate is carefully controlled to ensure the chocolate sets with the correct gloss, snap, and shelf-stable properties, locking in the precise dimensions and weight achieved up to this point.

The Unblinking Eye: In-Line Checkweighing and Quality Control

Even with a perfectly tuned forming and enrobing process, the potential for minute drifts in weight exists. Therefore, the most direct mechanism for ensuring consistency in the snickers production line is the implementation of in-line checkweighers. These are high-speed, automated scales integrated directly into the conveyor system.

As each individual bar exits the cooling tunnel, it passes over the checkweigher’s load cell. In a fraction of a second, the bar’s mass is measured with extreme accuracy. This is the final arbiter of weight consistency. The checkweigher is connected to the line’s control system and is programmed with very tight acceptable upper and lower weight limits. Bars that fall within this “green zone” are allowed to continue to packaging. However, the system is also designed to handle deviations.

- Underweight Bars: If a bar is detected as underweight, it is automatically rejected from the line. This is a non-negotiable quality standard. Allowing an underweight bar to be sold would be a violation of trade standards and consumer trust. Removing them also protects the bottom line by ensuring compliance.

- Overweight Bars: While less critical from a regulatory standpoint, overweight bars are also typically rejected. An consistently over-weight process represents a significant yield loss, as giving away excess product erodes profit margins over millions of units.

The data from the checkweigher is also aggregated and fed into a Statistical Process Control (SPC) system. This allows engineers to monitor the production process in real-time. Instead of just reacting to rejected bars, the SPC system can detect subtle trends—for instance, a gradual increase in average bar weight—allowing for proactive adjustments to the depositers or extruders before the process moves outside of specification. This creates a closed-loop system of continuous verification and correction, making the snickers production line a self-optimizing system for weight control.

The following table summarizes the key control points and their specific role in ensuring consistency:

| Production Stage |

Control Mechanism |

Primary Function in Consistency |

| Ingredient Preparation |

Density & Viscosity Control |

Ensures uniform physical properties of raw materials for predictable behavior in forming. |

| Forming & Layering |

Precision Extrusion & Volumetric Deposition |

Defines the core mass and dimensions of the bar before enrobing. |

| Cutting |

Multi-Wire Cutting System |

Guarantees identical bar length and width with minimal product waste. |

| Enrobing |

Tempering & Shaker Conveyors |

Applies a uniform coating layer and removes excess chocolate for weight control. |

| Final Inspection |

In-Line Checkweighing & SPC |

Provides 100% weight verification and enables proactive process adjustment. |

The Role of Sanitation and Maintenance in Operational Consistency

A less obvious but equally critical factor in maintaining consistency is the rigorous protocol for sanitation and preventative maintenance. A snickers production line is a complex arrangement of mechanical, thermal, and electrical systems. The consistent performance of these systems is a prerequisite for a consistent product.

For instance, even the most precise caramel depositer will perform erratically if its nozzles become partially clogged with crystallized sugar. Similarly, build-up on conveyor belts can alter the height of a product, affecting the enrobing curtain’s contact and thus the coating weight. Therefore, thorough and frequent cleaning is not just about food safety; it is a fundamental requirement for process stability. Preventative maintenance is its counterpart. Wear and tear on mechanical parts—such as the wires in the cutting system, the pumps in the depositors, or the bearings on conveyors—can introduce subtle variations over time. A scheduled maintenance program, where components are inspected, calibrated, and replaced before they fail or degrade, ensures that the entire snickers production line operates within its designed parameters day after day. This proactive approach minimizes unplanned downtime and, more importantly, prevents the gradual drift in product specifications that can occur with equipment fatigue.

Conclusion: A Symphony of Precision Engineering

The consistent size and weight of every bar is not the result of a single machine or process, but the culmination of a fully integrated and controlled system. The snickers production line is a symphony of precision engineering, where each stage is meticulously designed to contribute to the unwavering uniformity of the final product. From the foundational control of ingredient properties to the volumetric precision of the layering process, and from the clean definition of the multi-wire cutter to the regulated application of the chocolate coating, every step is a calibrated link in a chain of consistency.

The final, and perhaps most definitive, safeguard is the automated checkweigher, which acts as a gatekeeper, ensuring that only bars meeting the strict mass criteria proceed to the consumer. This end-to-end control, supported by rigorous hygiene and maintenance standards, provides the reliability that wholesalers and buyers depend on. It guarantees that every pallet, every case, and every individual bar delivered meets the same high standard, facilitating accurate forecasting, stable pricing, and ultimately, reinforcing the trusted relationship between the brand, the distributor, and the consumer. The snickers production line is, therefore, a masterclass in manufacturing excellence, where consistency is the primary and non-negotiable output.

中文简体

中文简体 English

English Français

Français عربى

عربى