In the confectionery industry, the final appearance and texture of chocolates and candies play a crucial role in consumer appeal. A glossy, smooth finish not only enhances visual attractiveness but also ensures product integrity and shelf stability. This is where Chocolate & Candy Polishing Machinery Equipment comes into play. These advanced systems are designed to apply even coatings, improve sheen, and maintain consistency across large production batches.

Key Advancements in Chocolate & Candy Polishing Equipment

The evolution of polishing machinery has been driven by the need for higher efficiency, reduced waste, and improved product quality. Traditional methods, such as manual panning or rudimentary drum polishing, have given way to automated systems that ensure uniformity and minimize human error.

One of the most significant advancements is the integration of IoT (Internet of Things) technology, allowing real-time monitoring of polishing parameters such as drum speed, temperature, and coating distribution. This data-driven approach enables manufacturers to adjust processes on the fly, reducing defects and optimizing resource use. Additionally, spray nozzle systems have become more precise, ensuring even distribution of polishing agents like cocoa butter, beeswax, or food-grade shellac.

Another notable development is the shift toward energy-efficient designs. Newer models feature variable-speed motors, improved heat retention, and reduced power consumption, aligning with sustainability goals. Furthermore, modular polishing systems allow manufacturers to scale operations without requiring entirely new setups, making them ideal for both artisanal producers and large-scale confectionery plants.

| Feature |

Traditional Polishing |

Modern Polishing Machinery |

| Automation Level |

Manual/Semi-Automated |

Fully Automated with IoT Controls |

| Coating Precision |

Inconsistent |

High Uniformity with Spray Systems |

| Energy Efficiency |

Low |

Optimized for Reduced Consumption |

| Scalability |

Limited |

Modular Designs for Flexibility |

These innovations demonstrate how Chocolate & Candy Polishing Machinery Equipment is transforming confectionery production, ensuring higher quality while reducing operational costs.

How Polishing Machinery Ensures Product Quality & Safety

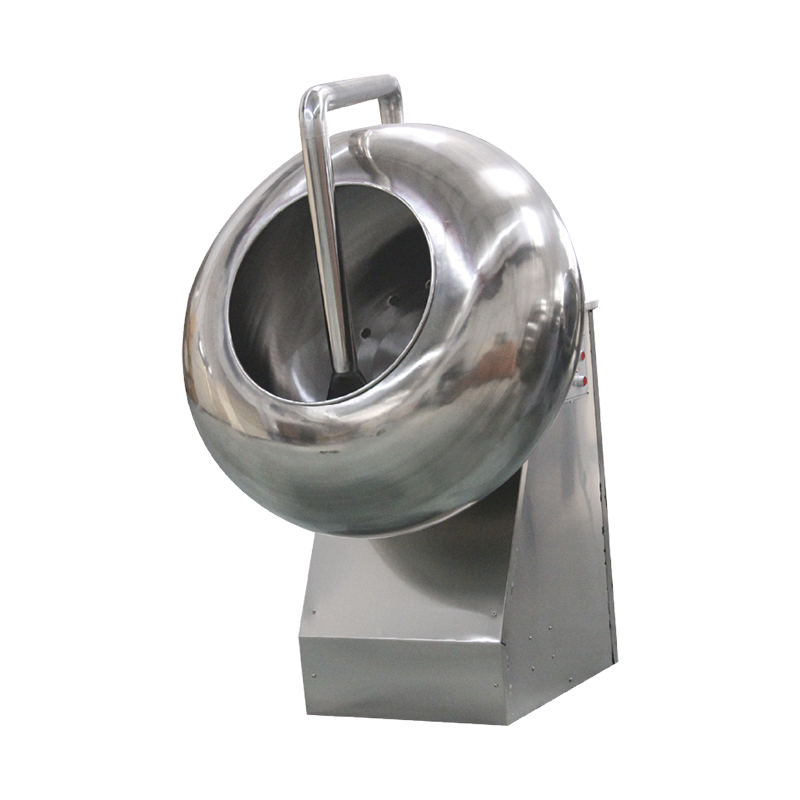

Food safety is a top priority in the confectionery industry, and polishing equipment must adhere to strict hygiene and material standards. Modern machines are typically constructed from stainless steel, which resists corrosion and is easy to sanitize. This is particularly important in preventing microbial contamination, especially in products with high sugar content that can attract moisture and bacteria.

Another critical factor is dust control. Polishing processes can generate fine particles, which, if not managed properly, may contaminate the product or pose respiratory risks to workers. Advanced dust extraction systems are now integrated into polishing machinery, maintaining a clean production environment while complying with occupational safety regulations.

Beyond safety, polishing plays a vital role in product longevity. A well-polished chocolate or candy has a protective layer that minimizes moisture absorption and oxidation, extending shelf life. For example, sugar-shelled candies benefit from a smooth polish that prevents cracking, while chocolate-coated products retain their shine without blooming (the white haze caused by fat separation).

Regulatory compliance is another key consideration. Equipment must meet FDA, CE, or other regional food safety standards, ensuring that polishing agents and machinery materials do not leach harmful substances. Manufacturers must also validate that their polishing processes do not introduce allergens or cross-contamination risks.

By integrating these safety and quality measures, Chocolate & Candy Polishing Machinery Equipment not only enhances aesthetics but also safeguards product integrity from production to consumption.

Choosing the Right Polishing Equipment: Factors to Consider

Selecting the appropriate polishing machinery depends on several factors, including production scale, product type, and budget. One of the first decisions manufacturers face is whether to use a batch polishing system or a continuous polishing system.

- Batch systems are ideal for smaller operations or specialty products where customization is key. They allow for precise adjustments between runs but may have lower throughput.

- Continuous systems, on the other hand, are designed for high-volume production, offering uninterrupted polishing with minimal manual intervention.

Another consideration is versatility. Some machines are optimized for specific confectionery types—such as hard candies, soft chews, or chocolate-covered nuts—while others offer adjustable settings for multiple products. Manufacturers should assess whether they need dedicated equipment or a multi-functional unit.

Maintenance and operational costs also play a significant role. Machines with self-cleaning mechanisms or easy-access components reduce downtime, while energy-efficient models lower long-term expenses. Additionally, manufacturers should evaluate the availability of spare parts and technical support to avoid prolonged disruptions.

Finally, future-proofing is crucial. As consumer trends shift toward organic, vegan, or clean-label confectionery, polishing machinery must adapt to new formulations. Investing in adaptable systems ensures that manufacturers remain competitive as market demands evolve.

Future Trends in Candy & Chocolate Polishing Technology

The confectionery industry is rapidly evolving, and polishing machinery must keep pace with emerging trends. One of the most prominent developments is the adoption of AI-driven optimization. Machine learning algorithms can analyze polishing data to predict inefficiencies, recommend adjustments, and even automate quality control by detecting surface imperfections.

Sustainability is another major focus. Manufacturers are seeking eco-friendly polishing agents, such as plant-based waxes, to replace traditional shellac or synthetic coatings. Water usage is also under scrutiny, leading to the development of dry polishing techniques that eliminate the need for liquid-based solutions.

Another trend is the rise of small-batch and artisanal production. Compact, user-friendly polishing machines are entering the market, allowing smaller producers to achieve professional-grade finishes without heavy investments. These systems often feature plug-and-play functionality, making them accessible to startups and craft chocolatiers.

Lastly, Industry 4.0 integration is transforming polishing operations. Smart factories now use interconnected systems where polishing machines communicate with other production line components, ensuring seamless workflow and real-time adjustments.

中文简体

中文简体 English

English Français

Français عربى

عربى