The chocolate industry has undergone a significant transformation in recent years, driven by consumer demand for intricate designs, personalized products, and high production efficiency. At the heart of this evolution is automatic chocolate design decorating machinery equipment, which enables manufacturers to achieve precision, consistency, and scalability in chocolate decoration. Unlike traditional manual methods, which are labor-intensive and prone to inconsistencies, automated systems leverage advanced robotics, digital printing, and smart controls to deliver flawless designs at high speeds.

Key Trends Driving Adoption of Automatic Chocolate Decorating Machines

The shift toward automation in chocolate decoration is influenced by several industry trends, each reinforcing the need for faster, more flexible, and sustainable production methods.

One of the most significant drivers is the integration of Industry 4.0 technologies, where smart sensors and IoT-enabled systems monitor and adjust decorating parameters in real time. This ensures optimal performance, minimizes defects, and reduces material waste—a crucial factor given the rising costs of cocoa and other ingredients. Additionally, data analytics from these systems help manufacturers refine processes for better efficiency.

Another major trend is the growing demand for customized chocolate products. Consumers increasingly seek personalized treats for events, corporate branding, or seasonal promotions. Automatic chocolate decorating machines excel in this area, offering capabilities such as high-resolution edible ink printing, laser engraving, and 3D pattern application. These technologies allow for intricate designs, including logos, text, and even photorealistic images, without compromising production speed.

Sustainability is also a key consideration. Traditional manual decorating often leads to excess material use and higher energy consumption. In contrast, automated systems optimize ingredient usage and reduce energy waste through precise dispensing mechanisms. Some machines even incorporate recyclable or biodegradable materials in their printing processes, aligning with the broader push toward eco-friendly confectionery production.

Technical Advancements in Chocolate Decorating Machinery

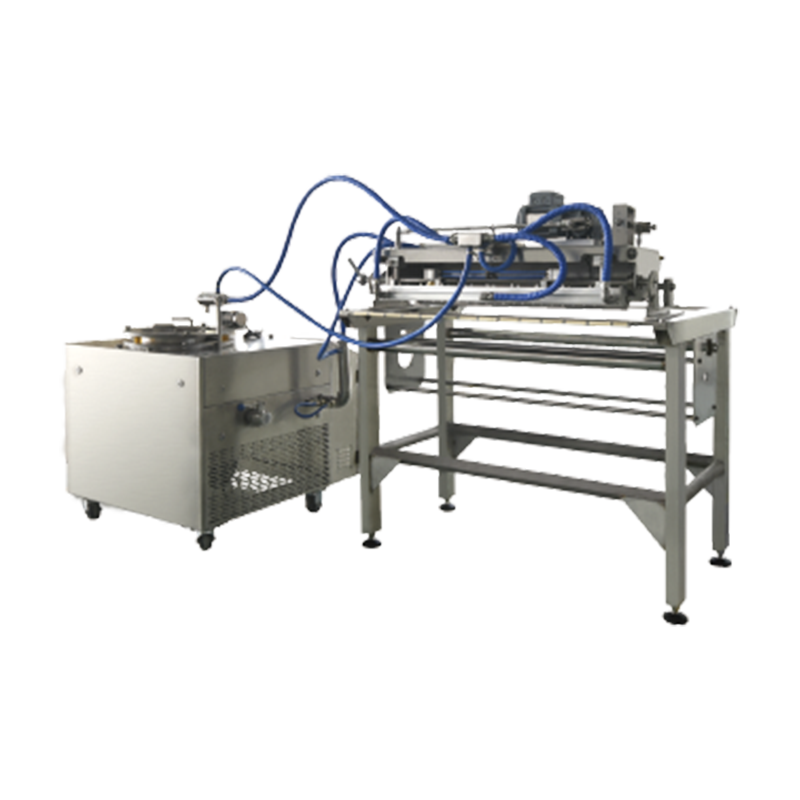

Modern automatic chocolate design decorating machinery incorporates several cutting-edge technologies that enhance functionality and output quality.

High-Resolution Printing and Laser Engraving

Edible ink printers and laser systems have revolutionized chocolate decoration by enabling ultra-fine details that were previously impossible with manual techniques. These systems can apply complex patterns, gradients, and even barcodes for traceability. Laser engraving, in particular, offers a contactless method for etching designs onto chocolate surfaces, ensuring no contamination while maintaining crisp lines.

Multi-Axis Robotics for 3D Decoration

Robotic arms equipped with precision nozzles or depositors allow for three-dimensional decorations, such as raised patterns, layered designs, and embossed textures. These systems can handle multiple chocolate types (dark, milk, white) and adjust for viscosity differences, ensuring consistent results across batches.

Hygienic and Food-Safe Design

Compliance with food safety standards is non-negotiable in chocolate production. Advanced decorating machines are built with easy-to-clean surfaces, stainless steel components, and enclosed mechanisms to prevent contamination. Many models meet certifications such as EHEDG (European Hygienic Engineering & Design Group) and FDA (Food and Drug Administration) requirements, ensuring they are suitable for large-scale food production.

| Feature |

Benefit |

| Smart temperature control |

Prevents chocolate bloom and ensures ideal viscosity for decorating. |

| Automated calibration |

Reduces setup time and minimizes human error. |

| Modular design |

Allows customization for different production needs (e.g., shapes, sizes). |

Challenges and Solutions in Implementation

Despite the advantages, adopting automatic chocolate decorating machinery presents certain challenges for manufacturers.

The initial investment cost can be substantial, particularly for small and medium-sized enterprises (SMEs). However, the long-term return on investment (ROI) often justifies the expense, as automation reduces labor costs, minimizes waste, and increases throughput. Some manufacturers opt for leasing models or phased implementation to ease financial pressure.

Another challenge is adapting the machinery to different chocolate types. Variations in cocoa content, viscosity, and tempering requirements can affect decorating precision. Modern machines address this with adjustable settings, real-time monitoring, and automated tempering controls to maintain optimal conditions.

Maintenance and operator training are also critical considerations. While automated systems reduce manual labor, they require skilled technicians for troubleshooting and upkeep. Many manufacturers now offer integrated training programs alongside machine purchases to ensure smooth operation.

中文简体

中文简体 English

English Français

Français عربى

عربى