Polishing machines remove surface defects from chocolate through a process that involves heat, friction, and re-crystallization of cocoa butter. Here's how it works:

Melting the Surface:

Polishing machines have a heating element that gently warms the surface of the chocolate. This heat softens the outer layer of the chocolate, making it more pliable and semi-liquid. It is important to note that the temperature must be carefully controlled to avoid overheating, which can cause chocolate to lose its temper and develop a dull appearance.

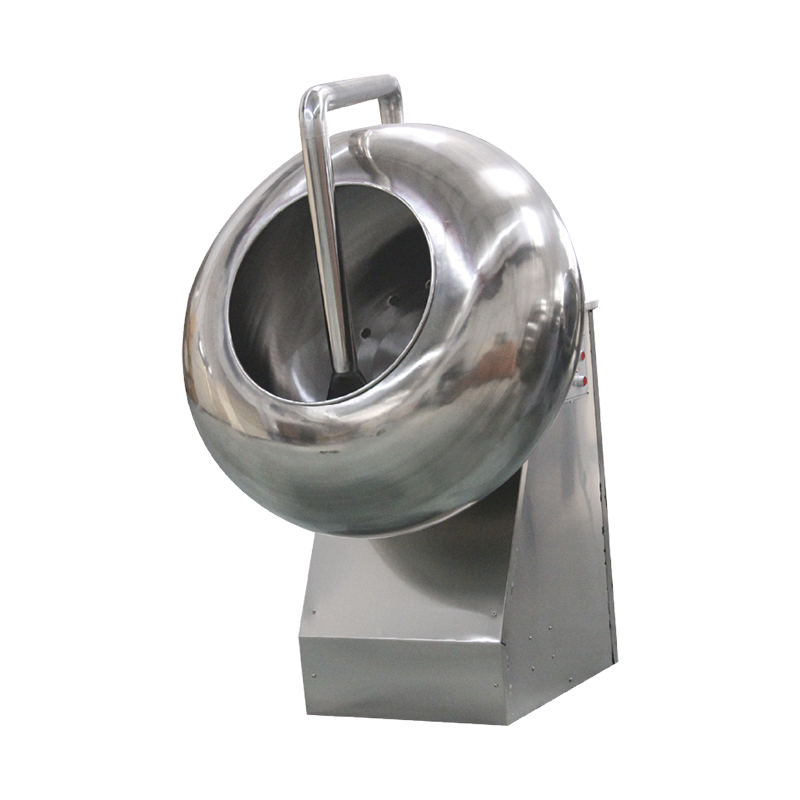

Friction: As the chocolate product moves through the polishing machine, it comes into contact with rotating polishing surfaces. These surfaces are typically made of stainless steel or other food-grade materials. The friction between the chocolate and the polishing surfaces helps to remove surface defects, such as air bubbles, streaks, or minor imperfections.

Re-crystallization of Cocoa Butter: The combination of heat and friction in the polishing process serves a crucial purpose: it re-crystallizes the cocoa butter in the chocolate. Cocoa butter has multiple crystal forms, and the goal is to encourage the formation of stable cocoa butter crystals, which give chocolate a smooth, glossy appearance. The re-crystallization process aligns these crystals, resulting in a uniform and shiny surface on the chocolate.

Cooling and Setting: After the surface defects have been removed and the cocoa butter has been re-crystallized, the polished chocolate moves to a cooling section of the machine. Here, the chocolate is allowed to cool and harden, locking in the improved texture and appearance achieved during the polishing process.

Quality Control: To ensure that the desired level of polishing has been achieved, chocolatiers often inspect the chocolates as they exit the polishing machine. Any remaining defects or irregularities can be addressed before the chocolates are packaged and distributed.

It's important to emphasize that the precise control of temperature and the quality of the polishing surfaces are critical factors in the effectiveness of a polishing machine. Maintaining the right temperature ensures that the chocolate remains in temper throughout the process, preventing issues like blooming or dullness. Additionally, using high-quality polishing surfaces minimizes the risk of introducing scratches or other imperfections during the polishing process.

In summary, a polishing machine removes surface defects from chocolate by carefully controlling temperature, applying friction to smooth the surface, and promoting the re-crystallization of cocoa butter to create a glossy and defect-free finish on the chocolate products. This process is essential for achieving the desired visual and textural qualities in chocolate products.

中文简体

中文简体 English

English Français

Français عربى

عربى