A chocolate moulding line is a sophisticated piece of equipment used in the chocolate production process to create molded chocolates with various shapes, sizes, and fillings. It streamlines the production of molded chocolates on a large scale, ensuring consistency in the final product. Here's how a typical chocolate moulding line works and its key components:

Chocolate Melting and Tempering: The process begins with melting solid chocolate into a liquid form using heated tanks or continuous melters. The melted chocolate is then tempered to stabilize the cocoa butter crystals, ensuring a glossy finish and a smooth texture in the final product. Tempering prevents undesirable characteristics like bloom (white streaks on the surface) and enhances the chocolate's shelf life.

Chocolate Delivery System: The tempered chocolate is fed into the moulding line through a delivery system. This system may use a series of pipes, pumps, and temperature-controlled channels to maintain the chocolate at the desired temperature throughout the process.

Moulds and Moulding Stations: The

chocolate moulding line consists of multiple moulding stations, each equipped with individual moulds. These moulds are made of food-grade materials and are designed to create specific shapes and designs for the chocolates. The moulds may be made of polycarbonate or silicone, depending on the complexity of the design.

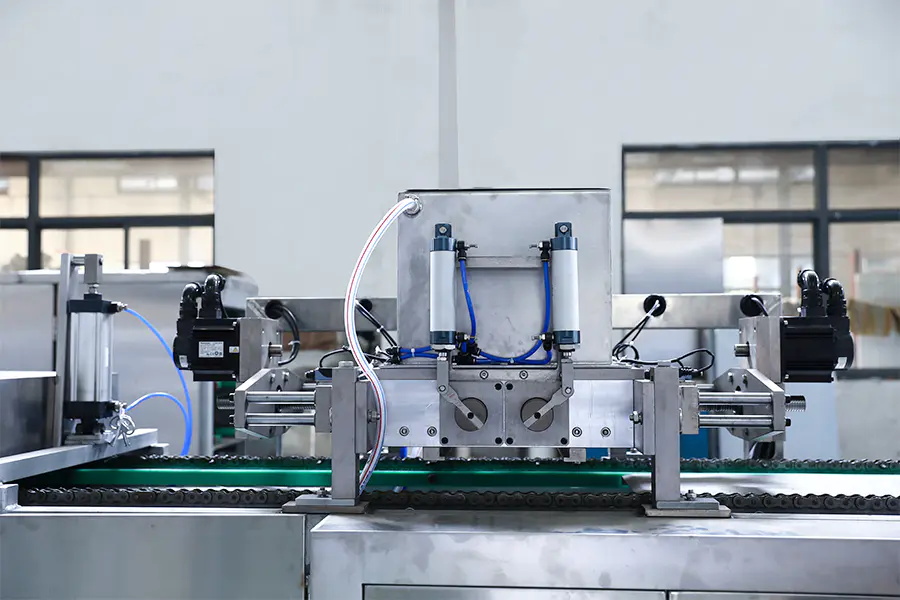

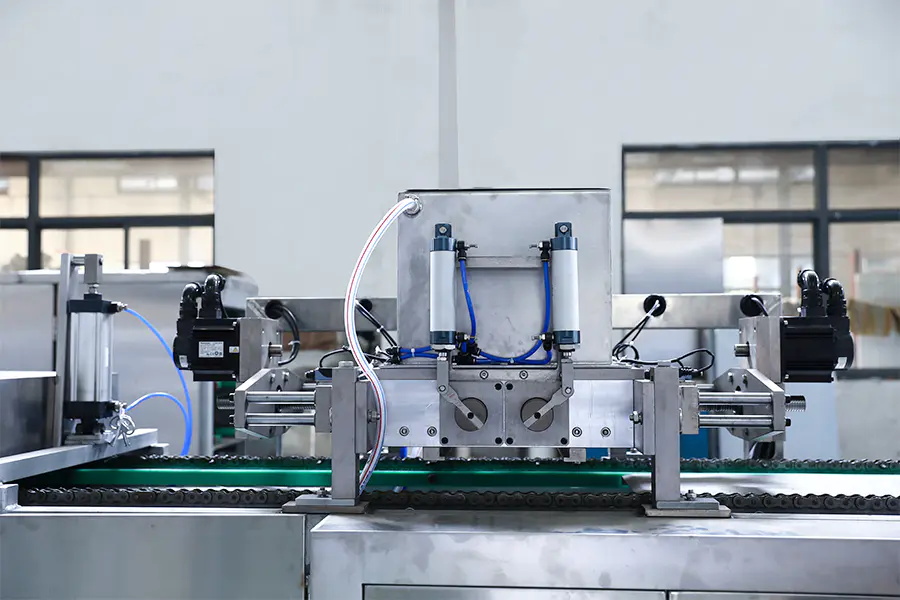

Depositing: The chocolate depositor is a crucial component of the moulding line. It precisely dispenses the tempered chocolate into the moulds, ensuring each cavity is filled uniformly to the required level. The depositor is equipped with a hopper that holds the tempered chocolate and a mechanism to control the flow rate for accurate filling.

Vibration and Air Removal: After depositing the chocolate, the moulds pass through a vibration stage. This helps remove any air bubbles trapped in the chocolate, ensuring a smooth surface finish and consistent density. It also helps in evenly distributing the chocolate within the mould.

Cooling and Solidification: The filled moulds are then conveyed through a cooling tunnel or refrigeration system. The cooling process solidifies the chocolate, allowing it to take the shape of the mould and maintaining its structure.

Demoulding: Once the chocolate has solidified, the moulds move to a demoulding station. Here, the chocolates are gently released from the moulds using air pressure or mechanical aids. The demoulding process is designed to preserve the intricate details and shapes of the chocolates.

Conveying and Packaging: The chocolates are conveyed to the end of the line, where they undergo quality checks for defects or imperfections. If the chocolates meet the quality standards, they proceed to packaging, where they are wrapped, boxed, or prepared for further distribution.

The key components of a chocolate moulding line work in harmony to produce a wide variety of molded chocolate products efficiently and consistently. Advanced moulding lines may also incorporate automation, control systems, and data monitoring to enhance productivity and ensure product quality.

中文简体

中文简体 English

English Français

Français عربى

عربى