The manufacturing of sweets has evolved through the years, with advancements in era revolutionizing the procedure. Among those improvements is the automatic chocolate moulding line, a complicated machinery that offers severa benefits over traditional guide strategies. In this text, we can explore the benefits of the usage of an automatic chocolate moulding line, together with elevated production efficiency, steady product pleasant, improved hygiene and cleanliness, decreased labor costs, and more advantageous protection.

Increased Production Efficiency

One of the important thing benefits of an

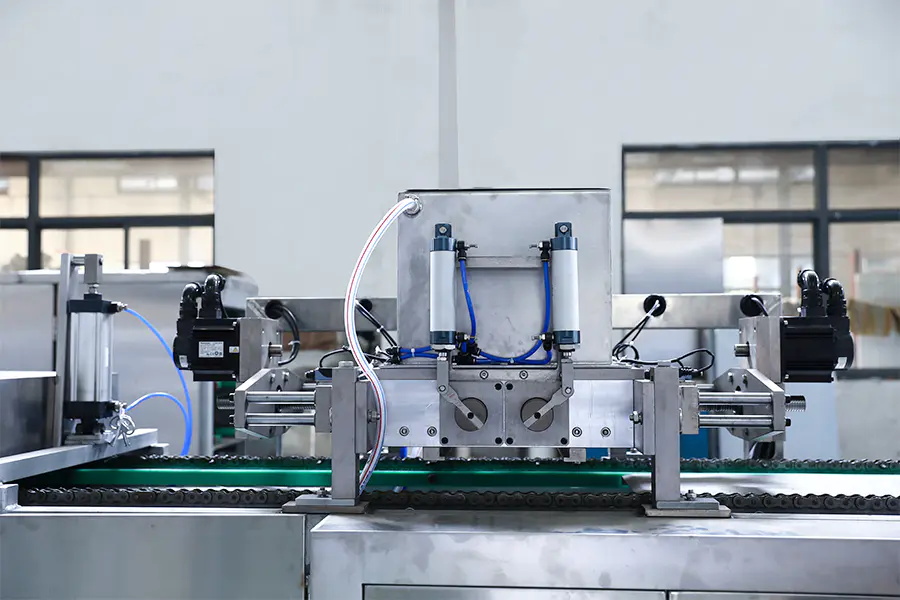

automated chocolateing line is its potential to significantly improve production efficiency. Manual methods are time-eating and hard work-intensive, requiring multiple people cope with numerous obligations. In assessment, an automated moulding line streamlines the complete manufacturing manner, from chocolate tempering toing and cooling. This automation results in a large increase in production velocity, permitting producers to satisfy higher demand and reduce time.

Consistent Product Quality

Achieving constant product high-quality is critical in the chocolate enterprise. Manual techniques are prone to human blunders, main to inconsistencies in length, form, and universal appearance of the sweets. On the opposite hand, an automated moulding line guarantees precise and steady moulding, ensuing in uniform candies whenever. The automated manner guarantees correct measurements and particular mold filling, contributing to a expert and appealing product.

Improved Hygiene and Cleanliness

Maintaining hygiene and cleanliness in chocolate manufacturing is paramount to ensure meals safety. Manual methods involve hand, growing the chance of cross-infection and compromising product satisfactory. An computerized chocolate moulding line minimizes human touch, for this reason lowering the probabilities of microbial contamination. Additionally, the equipment is designed with smooth-to-smooth components, taking into consideration green and sanitation, in the long run meeting meals safety requirements.

Reduced Labor Costs

Another widespread gain of an automatic moulding line is the reduction in exertions costs. While guide techniques require a workforce to perform diverse tasks, an automated requires fewer employees for supervision and protection. This permits manufacturers to allocate their personnel to different regions of production, saving prices in the end.

Enhanced Safety

Chocolate production entails working with warm temperatures and heavy equipment, risks to manual operators. An automatic moulding line mitigates those risks by way of eliminating the want for guide managing, reducing the of burns or accidents. Safety functions together with emergency stops and protecting guards further decorate the general safety of the system, protective each the workers and the product.

The advantages of the usage of an automatic chocolate moulding line are simple. From higher production performance to steady product pleasant, improved hygiene, decreased exertions costs, and more desirable protection, this advanced machinery considerably transforms the chocolate manufacturing industry. By making an investment in automation, producers can streamline their processes, increase productivity, and in the long run supply notable goodies to fulfill the needs of customers global.

中文简体

中文简体 English

English Français

Français عربى

عربى